Considering Upgrading Axles

As your offroading experience grows, the more technical trails will become more appealing. The more technical trails will be rockier, off camber, steeper and will require stronger components. We'll go over what to consider before upgrading axles as well as components required to build a strong axle to take the abuse the harder trails demand.

In this article:

Know Before You Go

So it's time to upgrade your axles? Reaching this decision means you've considered all the other possible upgrades prior to ripping your stock axles from underneath your vehicle. Many offroaders can get away with simpler upgrades to accomplish a reliable offroad axle. Upgrading from a limited slip ring and pinion to Lockers and Chromoly axle shafts over stock have all been been considered, right?

A novice offroader will learn very quickly that the factory ring and pinion will hold them back on the trail. The factory ring and pinion, in any vehicle, has a gear ration determined by the factory tire size. Your standard jeep will comes with a 225 tire or 29in diameter tire. By installing larger tires, typically 31-35in diameter the drivability of your vehicle will drastically change. The new diameter tire will effect the speedometer, odometer, gas millage average and take longer to accelerate. Swapping in a new ring and pinion gear ration can help offset these changes.

Most likely the differentials are "open" to make daily commuting smoother and quieter. An open diff allows the wheel on the outside of a turn to move at a faster speed than the inside wheel as it covers more ground. Differentials for offroading work a little differently. A ratcheting style "lunchbox" locker works when torque is applied aka apply throttle. As soon as any amount of throttle pressure is applied, the locker locks engages sending equal power to both wheels. Both axles are locked together and when the power is put down during turning the rear wheels will chirp and/or you'll hear a ratcheting noise coming from the rear end, both are normal but can get old while daily driving. You also have air lockers as an option too, if you'd like more information on ring and pinion upgrades check out our Lockers Article.

So you've already upgraded your gears? Okay, what about your axles shafts? The axles shafts are what run from your carrier out to the wheel, they take to the power from the transfer case, transferred to the ring and pinion via the driveshaft which then rotate the axels. When tackling obstacle, high rpm's, spinning tires and the vehicle jerking suddenly or stops against an obstacle can lead to an axle failure.

The material an axle is made out of along with spline count can decrease the chances of axle shaft failure. Size does matter when it comes to axles, the higher the spline count the larger the diameter, the larger the diameter the stronger the axle

In most cases, beginner offroader or street truck really don’t need upgraded axles as the abuse is pretty moderate. However, if you plan on doing more technical trails and limited street driving, it's time to upgrade to Chromoly axle shafts. Stock axles are made from 1040 and 1541 alloy steel, with a yield strength of around 42,000 psi. Meanwhile, Chromoly shafts are made of hardened 4340 steel with a yield strength of 125,000 psi. Need we say more?

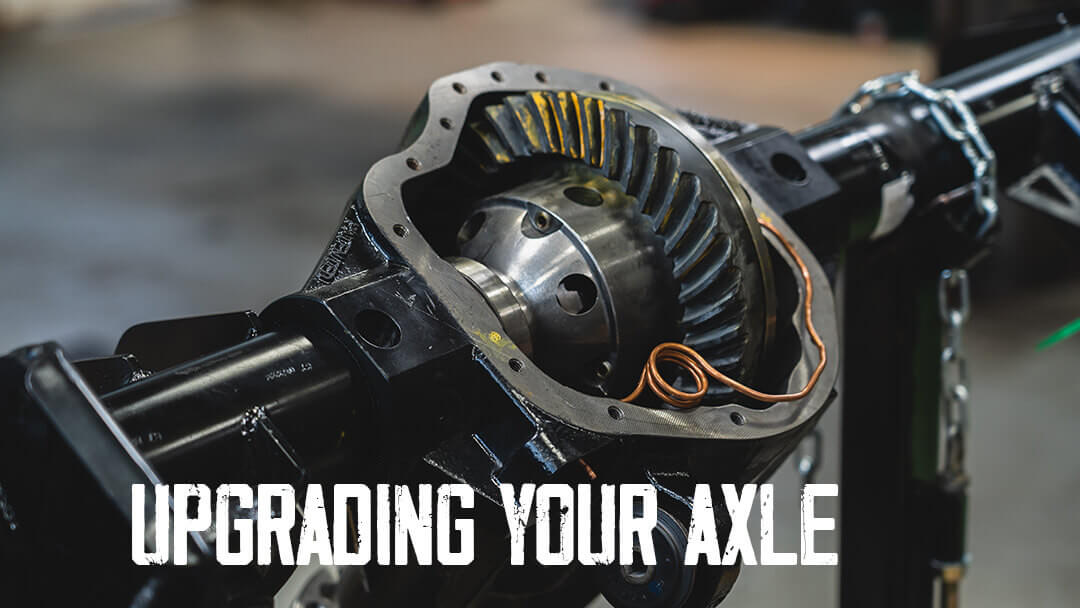

Upgrading Axles

If you made it to this point that means your stock axle components have been upgraded but still not cutting it. You've snapped and axle one too many times and your locker bit the dust. When upgrading axles you have two options. Find a used axle and rebuild it for your application or purchase a new axle built to your desired specifications and a direct bolt in. Both have there pros and cons but speak to professionals before you start to source a bolt in axle or start building one from scratch.

When upgrading axles it's important to know what you are staring with. For example, All four-door JK Wrangler have a Dana 44 in the rear. If you purchased the new JL Wrangler, it will have a Dana 30 front and Dana 35 rear axle, unless you specifically bought one with upgraded Dana 44s. All Rubicon JL owners have a Dana 44 front and rear axle.

Using the JK and JL as an example the Dana 44 axles are a stronger more reliable axle for offroading. So, a common swap for a JL, non Rubicon, would be to upgrade to a Dana 44. For the serious offroader the Dana 44 isn't going to cut it, they will swap to a full size Dana 60 axle, also known as a 1-Ton axle. The common factor in these upgrades will always be stronger more reliable components for a specific application. A daily driver jeep will never need 1-Ton axles, where as a serious offroader ditched the stock Dana 35 or 44 a long time ago. The key is to build axles for the your intended application, research, plan and speak to professionals to spend your money the best was possible.

Purchasing an Axle Package

If you love offroading but the technical side of components: splines, backlash, which year axle is compatible, Dana 60 or 44 is over your head maybe purchasing a complete ready to install axle is for you. Not everyone that goes wheeling is a savvy fabricator or has a shop to fab themselves up an new axle. Lucky for us companies like Dynatrac makes fully built Dana 44 and 60 direct bolt-in axle assemblies for popular applications. From mild builds for the enthusiastic offroader to axles built to handle extreme conditions Dynatrac builds axles based around which wheel size you run, vehicle and severity of the trails you drive.

Building Your Own Axle

Building an axle from scratch can be an overwhelming project, but it can be done if you do your homework.

There are many moving parts that all need to be planned for: which axle will you start with, what vehicle did the axle come out of, can you purchase mounting brackets for suspension, steering, what spline count, ring and pinion, axles seals, will my previous wheels bolt pattern work, setting the axle square before any welding and all new brakes. Each component has to be accounted for. People accomplish this project all the time, the information is out there so don't be afraid to ask. Fabrication and welding will be required, if you are a confident welder / fabricator this project is for you.

We'd love to hear from you!

If upgrading your existing axle fits the bill or swapping in a stout offroad- ready axle is for you we can help! Our pros can guide you through the entire upgrade process! Stop by our shop or visit us online today!